Technical Service of Measurement Systems and APCS

🛡️ Introduction

This page presents material on technical service of measurement systems and APCS, using an oil quantity measurement system as an example (clarification — one unit). This section is a shortened training and overview version. The Full version is a detailed manual for servicing such systems — practically a desktop book for leading engineers. It is also useful for managers, project leaders, as well as technical and administrative staff.

📘 Full version (on request)

Available on request — submit an application on the Contacts page. In the full version you will get:

- Features of service organization (structure, roles, SLA, Legal Shield).

- Step-by-step procedures for field operations.

- Technical “know-how” and proven solutions for measurement systems and APCS.

- Risk analysis and common operational mistakes observed on facilities.

🎯 Key parameters ensured by service

- Measurement accuracy and reliability of hydrocarbon accounting.

- System reliability and predictability of equipment performance.

- Elimination of disputes between supplier and buyer.

- Proper documentation preventing legal conflicts.

- Personnel safety, protection of health and life.

- Environmental sustainability — prevention of accidents and leaks.

✅ Customer benefits

The customer gains confidence that:

- The system is in reliable technical condition.

- Documentation is properly prepared and legally protective.

- The service organization not only performs the work but also provides optimization recommendations.

Thus, technical service is not a one-time inspection but a holistic system ensuring control, transparency, and legal protection of the customer’s interests.

📄 Technical Service Contract

A contract is the foundation of predictable and safe servicing of measurement systems and APCS. It defines the rules: who is responsible for equipment and data, how the work is performed, how documentation is handled, and how disputes are prevented. A properly drafted contract protects the Customer’s interests and eliminates chaos or “mess” in measurements.

The Full version of the Technical Service Guide is available on request via Contacts. It includes: typical risks in service and ways to mitigate them, analysis of real cases, a complete set of forms (protocols, acts, certificates, journals, checklists), reporting templates, and sample wording for legally sound documents.

✔️ Key provisions of the contract. Recommendations

Scope of work. The contract specifies the full list of operations: regular Service-1/Service-2/Service-3 and unscheduled work. For each item, the content is pre-defined (diagnostics, calibration, verification, software updates, redundancy tests) and the result delivered to the Customer: measurement protocols, acceptance and hidden work reports, certificates, entries in the electronic logbook. This level of detail avoids ambiguity and simplifies acceptance.

Responsibility boundaries. Roles are clearly distributed: the Customer provides access, conditions, support, and relevant input data; the Contractor is responsible for methodologies, standards, compliance with procedures, and proper documentation. This prevents disputes and “blurred” responsibility.

Access procedure. Work is carried out exclusively by the Pro meter service team. Third parties may be present only as Observers without the right to interfere. Any “self-activity” by outsiders breaks traceability, makes the protocol disputable, and turns the process into a “mess”. Therefore, any changes must be executed strictly under work orders, checklists, with signatures, and recorded in the logbook.

Document flow. The contract includes unified forms of checklists, reports, and protocols, rules for maintaining electronic logs and archives, as well as deadlines and reporting procedures. A unified format speeds up inspections and reduces human error.

Legal Shield. Wording is strictly in “complies / does not comply” terms with references to standards (OIML, API, ISO/IEC 17025, GOST). This gives documents legal strength and readiness for commissions and arbitration.

Work execution program (mandatory appendix). A separate 5–6 page document describing step by step: sequence of operations, service windows without process shutdown, control points, acceptance criteria, archive recovery procedures, interaction between Customer and Contractor, as well as procedures for special cases (modernization, emergency calls). The program makes the process predictable and manageable.

🏭 Object specifics

The contract specifies in advance the sites and work zones, responsible persons of the Customer, the procedure for issuing permits/work orders, requirements for transport and staff accreditation. This reduces conflict risks and simplifies interaction between Supplier, Receiver, and Representative.

📑 Contract appendices

- List of equipment and measuring instruments with valid certificates and their validity dates.

- Service schedule (Service-1, Service-2, Service-3, unscheduled work).

- Forms of protocols and reports (RU/EN), including hidden work reports.

- Safety instructions and data confidentiality procedures.

- Report with metrological analysis: accuracy assessment, equipment performance analysis, recommendations for system improvement.

- Information on new solutions and current innovations in metrological service.

- Service program — step-by-step work execution plan (mandatory appendix).

🧭 Role naming style

On the website and in documents, roles are written with a Capital letter: Customer, Supplier, Receiver, Representative, Contractor. (In EN: Customer and other parties — also capitalized).

Such a contract eliminates chaos and “mess”, makes the process transparent and legally sound, and protects the Customer’s interests both in daily operation and during inspections or arbitration.

📊 Scope of Work and Stages of Technical Service

The scope and structure of technical service depend on the goals and tasks, as well as on the capabilities and schedule of the Customer. We divide technical service into several levels:

- daily,

- Service-1 (monthly),

- Service-2 (quarterly),

- Service-3 (annual),

- and also unscheduled service.

🛠️ Daily Service

Daily operations are usually performed by the company’s maintenance staff; however, under an outsourcing contract Pro meter specialists provide continuous monitoring and support. These include:

- visual inspection of equipment,

- detection of visible faults,

- checking displays and APCS upper-level operation,

- report printing,

- communication channel verification,

- keeping logs and analyzing events and failures.

🔧 Service-1 (monthly)

Service-1 includes all daily operations and adds system-specific tasks for each measurement node. It covers metrological characteristic checks, verification of APCS functions, redundancy nodes, parameter adjustments, and deviation analysis.

📐 Service-2 (quarterly)

Service-2 builds on Service-1 and includes metrological control of measuring instruments and the system as a whole. Results are documented by verification protocols, and if necessary, calibration protocols. A quarterly service report is prepared.

The main feature of Pro meter is flexibility: we shift part of Service-3 tasks into Service-2. This unloads the annual cycle and gives more attention to critical measuring instruments.

⚙️ Service-3 (annual)

Service-3 focuses on the essentials: servicing and verifying the main measuring instruments. In a typical oil custody transfer system, this includes:

- flowmeters on measurement lines,

- online densitometers,

- provers (including cleaning systems for capacity determination),

- sampling devices,

- secondary equipment (controllers, data transfer and protection units).

All work related to IT systems.

Results are documented in a report, which must include:

- List of measuring instruments with numbers and verification certificate dates,

- Verification/calibration protocols,

- Metrological analysis of the measurement system,

- Annual service report and acceptance certificate.

🚨 Unscheduled Service

Performed at the Customer’s request. Response/readiness time is defined in the contract, and this factor significantly affects the contract cost. The scope of work may apply to a part of the custody transfer unit or to the whole measurement system.

Pro meter Advantage

Unlike government or departmental structures, we are dynamic and mobile. Our methodology allows redistributing workload between Service-2 and Service-3, maintaining balance: part of auxiliary tasks are carried out earlier, while annual work focuses on the core — accuracy and reliability of measurements.

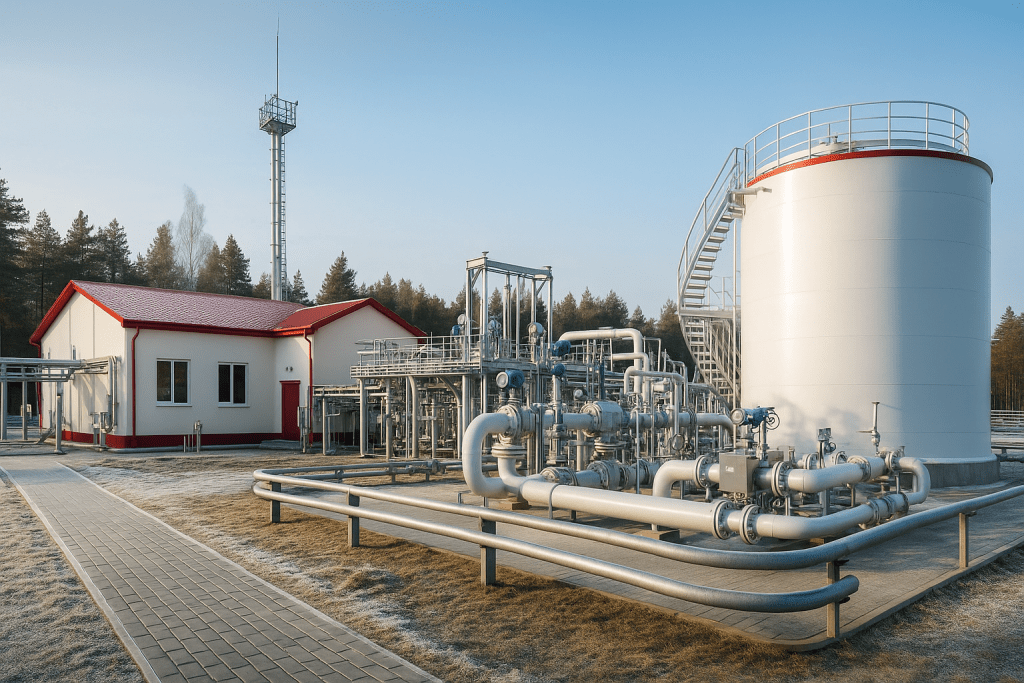

Resources and partnership. Pro meter performs service independently or in partnership with SIA Olimps engineers, which enhances our competence and coverage.

📘 Operation Manual for Measurement Systems and APCS

🎯 Purpose and Principle

The operation manual is a comprehensive document (100+ pages), a true “bible” for operators and the service team. The main principle is interchangeability: when switching the service organization, any leading engineer of another company must be able to carry out all regulatory work without delving into hidden project details or local specifics. Therefore, the manual describes not only “what to do” but also “how, in what sequence, and according to which methods”. The document is localized to the site: taking into account premises, infrastructure, access, climate, and safety requirements.

🧩 What the manual includes

- Technological process regulations: single-line and combined diagrams, interaction of technology and automation.

- Maintenance regulations: list of measuring instruments and auxiliary equipment, list of standards, maintenance actions according to factory recommendations and regulations.

- Work procedures for the service scope with references to methods and standards (calibration, verification, tests, tolerances, acceptance).

- Measurement specifics: peculiarities in calibrations/verifications, requirements for conditions, tolerances, and documentation of results.

- Illustrations, checklists, protocol and report forms, examples of completed documentation.

🔄 Document life cycle

The manual is created from the design stage and serves as a reference for designers and programmers. During commissioning, the document is updated, and after pilot-industrial operation it is supplemented with factual data: optimized procedures, refined steps, removal of redundant actions. The result is safe, convenient, and reliable operation.

The Full Technical Service Guide and the Design & Engineering Guide for custody transfer systems, measurement systems, and APCS are available. In the full version you will find: risks and specifics of operation, practical details, Pro meter know-how, extended examples, as well as a complete set of forms (protocols, reports, certificates, journals, checklists) — a section volume of 100+ pages. Request access via the Contacts page.

🗂️ Technical Service Documentation

Documentation ensures a complete reflection of both the technical and legal aspects related to the facility. We maintain both paper forms and electronic registers with version control and digital signatures/timestamps. All records are bilingual (RU/EN when required) and aligned with standards and the site’s internal regulations.

📄 What is documented

- Reports and protocols by service levels (Service-1/Service-2/Service-3), including hidden work reports.

- Register of measuring instruments with verification/calibration certificates and their validity dates.

- Logs of events, failures, interventions, configuration changes (change log).

- Final service reports, metrological analysis, list of recommendations, and KPI summary.

- Electronic data archive and chain-of-custody for exports/transfers to third parties.

💾 Storage and database

Archives are backed up, protected, and stored according to the retention policy defined in the contract. Access is role-based (Customer, Contractor, Representative) with activity logging. For inspections we provide a “one-click package”: list of instruments with certificates, protocols, reports, and log copies.

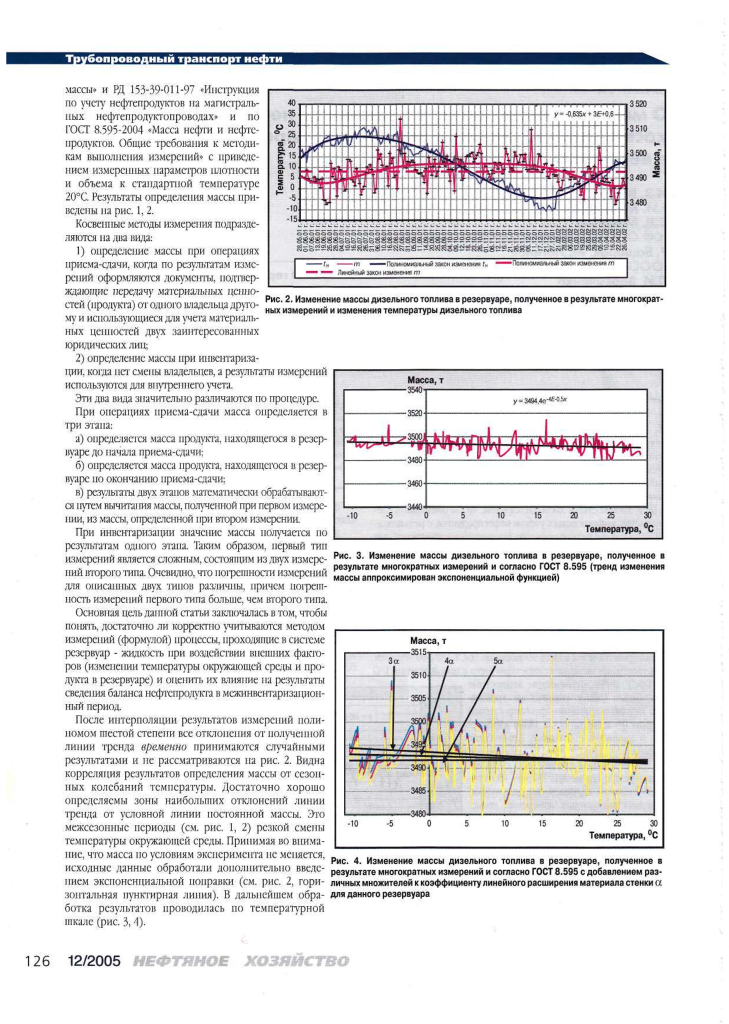

Proper and well-structured archiving has allowed Pro meter to build a multi-year database (15+ years) of operation of measuring and auxiliary equipment. This database contains complete metrological analyses, recommendations for improving technical performance, and enhancing measurement accuracy.

For manufacturers, the database serves as a feedback tool: it provides a foundation to improve instrumental characteristics, refine designs, and achieve higher accuracy at the equipment level. This is one of the key methods of improving measurement accuracy — precisely at the instrumental level.

Full form templates, sample entries, and checklists are available in the Full Service Guide. Interested in accessing the database or methods of improving accuracy? Submit a request via the Contacts page.

📏 Measuring Instruments and Standards. Cooperation with Accredited Laboratories

Below is a list of basic measuring instruments, given as an example of a typical oil custody transfer unit. In reality, Pro meter covers a wide range of instruments for verification, calibration, and metrological analysis, including equipment for the energy sector, gas industry, and scientific research. This approach allows us to work with industrial enterprises as well as universities, research institutes, and instrument manufacturers.

🧰 Measuring Instruments (Metering System)

- Flowmeters: Coriolis, turbine, ultrasonic (single-path and multipath).

- Online densitometers, pressure and temperature sensors, flow computers/controllers.

- Sampling devices, sample preparation units, data transfer/protection systems.

- For each instrument we maintain a register of verification/calibration certificates with numbers and validity dates.

🎚️ Standards and Reference Sets

- Provers (including cleaning systems and capacity determination), standard tanks.

- Laboratory densitometers, reference balances, weight sets, pycnometers.

- Auxiliary standards: reference thermometers/barometers, reference pressure/temperature devices.

- Full traceability to national/international standards.

🧪 Cooperation with Accredited Laboratories

Pro meter works with national and regional accredited laboratories (ISO/IEC 17025). Together we perform verifications and calibrations, adapt methods to the facility, and document results according to international requirements (OIML R 117, API MPMS, GOST/ISO). In the end, the laboratory issues official certificates, while our protocols and raw data form part of the Customer’s document package.

⚖️ Legal Shield: Recognition of Results

All documents are formulated unambiguously (“complies / does not comply”) with direct references to standards. This ensures recognition of measurements during audits and arbitration, and provides legal protection of the Customer’s interests.

🏭 Value for Instrument Manufacturers

Our archival database (15+ years of real operation of instruments and auxiliary equipment) is valuable material for R&D. Based on metrological analysis and field protocols, manufacturers receive feedback for improving the instrumental characteristics of their devices — one of the key methods for increasing accuracy at the “instrumental” level. The database helps identify drifts, environmental influences, algorithmic nuances, and confirm the effect of upgrades.

The full set of methods, sample protocols/certificates, and completed documentation examples is available in the Full Version. Request access via the Contacts page.

📑 Metrological Analysis and Report

⚖️ Legal significance

The metrological report is a legal document that forms the basis for signing the acceptance certificate of completed work. Such reports are reviewed at the state level, especially during the acceptance of large facilities and international projects. Proper documentation prevents “fake” protocols and provides the Customer with reliable protection of interests in case of disputes or arbitration.

🎯 Purpose of analysis

The purpose of metrological analysis is to confirm the metrological characteristics of equipment and the system as a whole. But not only that: applied science is also involved — analyzing the performance of instruments under real operating conditions. Based on our database (15+ years), we identify weak points, assess reliability and accuracy, and propose improvements. For manufacturers, this is feedback from the field: operating engineers provide factories with factual information about equipment performance in various conditions. Such data helps modernize designs and improve the instrumental accuracy of devices.

📋 What the report includes

- List of measuring instruments with numbers and dates of valid verification/calibration certificates.

- List of auxiliary equipment and systems.

- Analysis of event and failure logs for the service period.

- Checklist marks confirming completion of all regulatory tasks.

- Recommendations for improving custody transfer units, measurement systems, and APCS.

🔎 Final result

The final stage of technical service turns maintenance into a management tool. The Customer receives not only reliable equipment but also an analytical foundation for strategic decision-making. The report is issued as a package of documents: test protocols, verification/calibration certificates, and an annual report with analysis and recommendations. These documents pass any inspection — from internal audits to international reviews. For the Customer, this is “insurance” against disputes and guaranteed legal protection.

📂 Full Reports on Request

In addition to standard final documentation, we provide full technical service reports — including extended metrological analysis, detailed protocols, attached certificates, KPI reports, and modernization recommendations.

These reports can be used not only for internal audits and government inspections but also as a basis for scientific research and for manufacturers to improve their instruments.

Request access to the full versions of reports via the Contacts page.

Customer Outcome

What the Pro meter technical service program guarantees.

- The system is kept in reliable technical condition.

- Documentation is properly prepared and legally protects the Customer’s interests.

- The service organization not only performs the work but also provides optimization recommendations.

- Together with a functioning system, the Customer receives a document package (protocols, certificates, reports) that protects them during audits, inspections, and litigation.

Practical Benefits

Technical service is not only preventive maintenance but also reduces legal risks and saves budget through proper documentation, predictable procedures, and transparent acceptance of work.

Who Benefits Most

- Industrial enterprises and terminals (custody transfer unit operators).

- Traders and logistics companies.

- Laboratories (including those preparing for or expanding ISO/IEC 17025 accreditation).

- Equipment suppliers and dealers (deliveries with legal clearance and readiness for inspections).

📚 Regulatory Framework and Methodologies

A list of key standards relied upon by Pro meter. The full register with versions is available on request via the Contacts page.

🌍 International

- ISO/IEC 17025 — competence of laboratories.

- ISO 9001/14001/45001 — management systems.

- ISO 5167 — flow through differential devices.

- ISO 6976/6974/6975 — gas analysis and properties.

- ISO 4267/4787/3838 — density, tanks, glassware.

🏭 Industry-specific

- OIML R 117 — fuel measuring systems.

- API MPMS — measurement of oil and petroleum products.

- AGA Reports 3/7/8/9/10 — gas flow.

- ASTM D-series (D1250 and others).

🇷🇺/🇪🇺 National

- GOST / GOST ISO / GOST R.

- MI/RMG/PR — verification methods.

- EN / IEC — electrical, explosion-proof, IT security.

- Customer’s technical documentation and site regulations.

🧪 Pro meter Internal Regulations

- Service checklists (Service-1/Service-2/Service-3, unscheduled).

- Forms of protocols, reports, journals.

- Methods for calculating uncertainty and M-factors.

- Data archive and chain-of-custody.

Pro meter — Technical Service of Measurement Systems and APCS

Legally robust results, traceability of measurements, and practical value for operation and R&D. Database with 15+ years of experience, full package of methodologies and forms — available on request.

What You Get

- Service-1 / Service-2 / Service-3 + unscheduled works by program.

- Protocols, certificates, metrological analysis.

- Legal Shield — readiness for audits and arbitration.

Regulatory Support

- ISO/IEC 17025, OIML R 117, API MPMS.

- ISO 5167, ASTM D-series, AGA Reports.

- GOST / GOST ISO / GOST R + Customer’s technical standards.